REHAU Sustainability

EcoPuls: A far-sighted promise to every generation

What will the world be like in 30 years?

Nobody can answer that for us. Nevertheless, we must not stop asking. Our partner REHAU takes the issue of sustainability seriously – and has found an answer: Through circular economy, REHAU wants to continue to increase the proportion of recycled plastic in the various window systems. The REHAU premium quality always guarantees a maximum service life of the windows, which, thanks to their high energy efficiency, also contribute significantly to the conservation of resources during the use phase.

This is a promise and our commitment. In this way, we make an important contribution to protecting our planet.

REHAU EcoPuls – circular economy

Our promise in practice

Global challenges, such as climate change and sustainable lifestyles, require new solutions, especially from the economy. Consumption and production must move away from single-use, because waste is not a sustainable approach. For REHAU, the circular economy has therefore developed into one of the guiding principles over the last three decades.

Production

All European REHAU factories have been certified with the independent product label VinylPlus due to their sustainable production processes.

Products

REHAU EcoPuls window profile systems are unique in the window industry when it comes to a closed cycle economy. The result: up to 97,000 t of CO₂ savings annually.

Collection

Old PVC windows are a valuable resource for new plastic windows. REHAU maintains a large network to collect this material.

Recycling

REHAU EcoPuls window profile systems are unique in the window industry when it comes to a closed cycle economy. The result: up to 97,000 t of CO₂ savings annually.

Extrusion

The unique REHAU extrusion process enables the production of window profiles that are made from recycled material on the inside.

We take responsibility – holistically

REHAU has always been committed to using raw materials economically and efficiently. As a member of the UN Global Compact, REHAU supports the United Nations’ “Sustainable Development Goals”. As REHAU partners, we make our contribution every day to make these goals a reality.

Systematic collecting

To ensure effective scrap material recovery, a large, Europe-wide network with almost 2,000 partners was set up through which scrap material is collected. These are either profile sections made from production waste or complete old windows.

Professional preparation

The processing takes place in specially set up recycling plants. They are the key to consistently implementing our sustainability promise. A total of 70,000 tons of PVC are recycled this way every year. This corresponds to approximately 7 times the weight of the Eiffel Tower and is enough to cover REHAU’s entire recyclate needs.

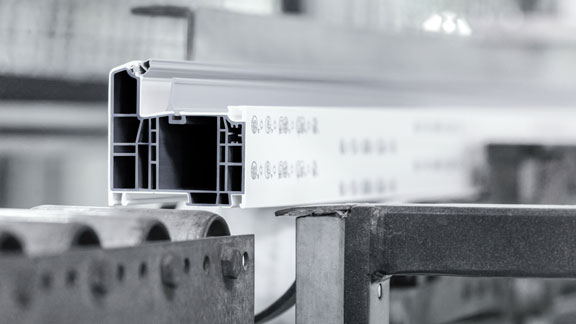

Unique extrusion process

During extrusion, the PVC is shaped under pressure. The outer surface is made from new plastic. In the EcoPuls profiles, the invisible inner parts are made from recycled material. The proportion of recyclate varies between 40% and 75% and will continue to be increased in the future.

Audited sustainability in all plants

All four of REHAU’s European window factories have been certified by the independent product label VinylPlus. This means that they meet all the sustainability criteria that are imposed on the PVC industry: from raw material procurement and material cycles to recycling. REHAU is one of the few system houses that can demonstrate this standard across Europe.

Sustainable in use

As a REHAU partner, we bring the EcoPuls windows back to you. Combined with triple insulating glazing, they achieve exemplary U w values and energy savings of up to 76%*.

The installation has two advantages: the heating cost savings during the usage phase and the good feeling of also supporting the environment with a sustainably produced product.

*Reduction in energy loss on the window when changing from old wooden/plastic windows from the 1980s (U f : 1.9; U g = 3.0) to windows made of GENEO RAU-FIPRO X profiles (U f = 0.86 ; U g = 0.5), window size 123×148 cm

40% of our profiles are already made with recycled material. 40 to 75% recycled material is already processed in EcoPuls profiles.

97,000 t of CO2 are saved per year through the use of recycled material. This corresponds to the binding power of 7.8 million trees, a forest the size of Berlin.

REHAU processes 70,000 t of waste material every year. That’s roughly 7 times the weight of the Eiffel Tower.

88% less CO2 is produced when producing recycled plastic compared to producing new material.